Customized Solutions for Industrial Cleaning and Power Equipment

Core Objectives of the Solutions

Addressing the core needs of global industrial enterprises in equipment maintenance, production environment optimization, and efficient operation of power systems, we rely on our three core product lines—dry ice cleaning machines, industrial dust collectors, and air compressors—to provide a full-process customized service covering “diagnosis-configuration-implementation-after-sales support”.

Our goal is to help customers reduce operation and maintenance costs, improve production efficiency, meet environmental compliance requirements, and adapt to industrial standards and voltage specifications in different countries and regions.

Industry-Specific Solutions

Automotive Manufacturing Industry

Industry Pain Points

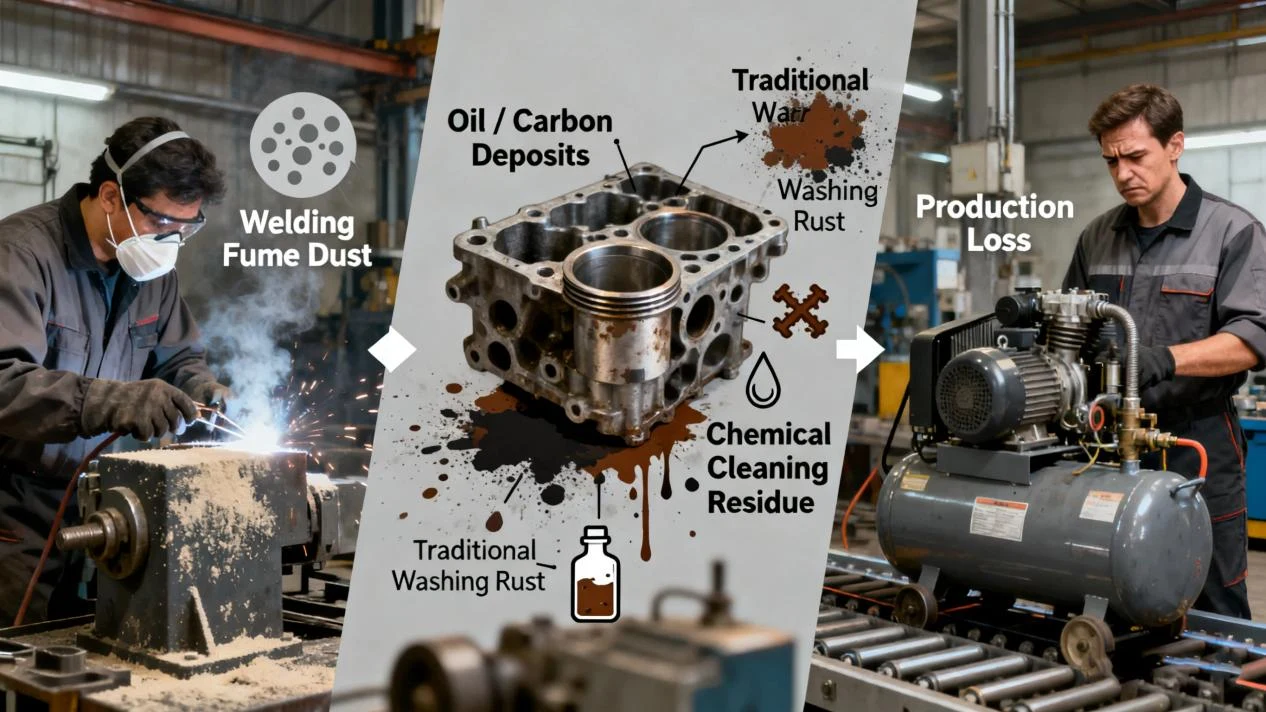

·High concentration of welding fumes and dust in welding workshops, which endangers employees’ health and easily adheres to equipment, affecting precision;

·Difficulties in cleaning oil stains and carbon deposits on precision components such as engines and gearboxes. Traditional water washing tends to cause rust on components, while chemical cleaning leaves residues.

·The power system of the production line requires stable air supply, and air compressor failures may lead to production downtime losses.

Solution

·Industrial Dust Collectors: Equip with mobile welding fume extractors or central dust collection systems to accurately capture dust at welding stations, with a filtration efficiency of 99.9%. Compliant with environmental standards such as EU CE and US OSHA to ensure workshop air quality.

·Dry Ice Cleaning Machines: Adopt dry ice pellets at -78.5°C to quickly remove oil stains and carbon deposits from component surfaces without disassembling equipment. No secondary pollution is generated, and components can be put into production immediately after cleaning without drying, suitable for batch cleaning of auto parts.

·Air Compressors: Provide screw air compressors integrated with intelligent frequency conversion systems. The output is automatically adjusted according to the air demand of the production line, achieving an energy-saving rate of 20%-30%. Meanwhile, air storage tanks and dryers are equipped to ensure clean and moisture-free compressed air, avoiding damage to pneumatic components.

Food Processing Industry

Industry Pain Points

·Dust (e.g., flour, starch) in production workshops is prone to explosion risks and must comply with food safety standards such as FDA and EU 10/2011.

·Food residues remain on baking molds and conveyor belts. Traditional cleaning methods easily cause cross-contamination and require frequent downtime.

·Pneumatic equipment on the production line has extremely high requirements for the purity of compressed air. Oil-containing or moisture-containing air will contaminate food.

Solution

·Industrial Dust Collectors: Select food-grade stainless steel dust collectors equipped with HEPA high-efficiency filtration units. They can collect fine dust to prevent cross-contamination, and the equipment is easy to clean, meeting the hygiene requirements of the food industry.

·Dry Ice Cleaning Machines: Use food-grade dry ice for cleaning, with no residues or secondary pollution. Online cleaning of baking molds, conveyor belts, and other equipment is achievable without disassembly, reducing downtime and ensuring production continuity.

·Air Compressors: Supply oil-free screw air compressors combined with multi-stage filtration systems. The oil content of the output compressed air is less than 0.01mg/m³, meeting the cleanliness requirements of pneumatic equipment (e.g., filling and packaging equipment) in food processing.

Electronic Manufacturing Industry

Industry Pain Points

·Solder paste dust and resin dust generated during circuit board production easily affect product quality, and electrostatic interference must be avoided.

·Cleaning oil stains and dust on precision electronic components (e.g., chips, sensors) is difficult, and traditional cleaning methods tend to damage components

·he electronic equipment assembly line requires stable and clean compressed air. Air pressure fluctuations or air impurities may cause equipment failures.

Solution

·Industrial Dust Collectors: Configure anti-static dust collectors with anti-static filter materials to effectively collect solder paste dust and resin dust, preventing electrostatic interference to electronic components. Meanwhile, the equipment has high filtration efficiency, ensuring that the workshop cleanliness meets electronic industry standards.

·Dry Ice Cleaning Machines: Adopt micro-particle dry ice cleaning technology, with adjustable cleaning pressure (minimum 0.1MPa). It can gently remove oil stains and dust from the surface of precision electronic components without damaging them, leaving no residues and requiring no subsequent drying.

·Air Compressors: Provide silent oil-free air compressors with an operating noise of less than 65dB, avoiding impact on the production environment of electronic workshops. Meanwhile, precision filters and dryers are equipped to ensure that the dew point of compressed air is below -40°C, with no oil, moisture, or impurities, guaranteeing stable operation of pneumatic equipment.

Chemical Industry

Industry Pain Points

·Chemical residues and scaling easily adhere to the inner walls of reactors and pipelines. Traditional cleaning methods (e.g., high-pressure water jet, chemical cleaning) tend to corrode equipment, and the treatment cost of cleaning waste liquid is high.

·Toxic and harmful dust (e.g., pigment dust, catalyst dust) generated during chemical production must be efficiently collected to prevent environmental pollution and harm to employees’ health.

·The power system of chemical equipment has high requirements for the reliability of air compressors. Equipment failures may cause interruptions in chemical reactions, resulting in significant losses.

Solution

·Dry Ice Cleaning Machines: Adopt high-pressure dry ice cleaning technology. When dry ice pellets impact the equipment surface, they sublime instantly, with a volume expansion of 800 times. This can quickly peel off chemical residues and scaling on the inner walls of reactors and pipelines, with no corrosion or secondary pollution. Zero cleaning waste liquid is generated, reducing environmental treatment costs.

·Industrial Dust Collectors: Select dust collectors made of corrosion-resistant materials (e.g., PP plastic, 316L stainless steel), equipped with explosion-proof motors and filter materials. They efficiently collect toxic and harmful dust and are equipped with a dust concentration monitoring function, which automatically alarms when the concentration exceeds the standard, ensuring compliance with environmental and safety standards in the chemical industry.

·Air Compressors: Provide high-pressure screw air compressors with a pressure range of 1.0-1.6MPa, meeting the high-pressure air demand of chemical equipment (e.g., pneumatic valves, mixing devices). Meanwhile, the equipment is equipped with dual overload protection, temperature monitoring, and other safety devices, with a low failure rate, ensuring continuous production.

Implementation Guarantee of the Solutions

Preliminary Research and Customization

·Establish a professional technical team to gain in-depth understanding of the customer’s industry characteristics, production processes, equipment parameters, and pain points through online communication and on-site investigations (for key customers).

·Based on the research results and combined with the industrial standards (e.g., voltage, interface specifications, environmental regulations) of the customer’s country/region, formulate a personalized equipment configuration plan, and provide an equipment selection list, technical parameter sheet, and cost-benefit analysis report.

Delivery and Installation

·Provide global logistics and distribution services, cooperating with well-known freight forwarders to ensure that equipment is delivered to the customer’s designated location on time and safely. Meanwhile, provide a complete set of customs clearance documents (e.g., commercial invoice, packing list, certificate of origin, CE/FCC/UL certification documents) to assist customers in smooth customs clearance。

·Dispatch professional technical engineers for on-site installation and commissioning (or provide remote guided installation services) to ensure the normal operation of the equipment. Conduct on-site training for customer operators, covering equipment operation procedures, daily maintenance, safety precautions, etc., and provide training manuals and video tutorials.

After-Sales Support

·Establish a 7×24 global after-sales service system. Customers can consult at any time through phone, email, online customer service, etc. The technical team will respond within 1 hour and provide solutions within 24 hours.

·Provide equipment warranty services (1-2 years warranty for dry ice cleaning machines and air compressors, 6 months warranty for industrial dust collector filter materials). During the warranty period, free maintenance parts and on-site maintenance services are provided.

·Conduct regular return visits to customers to understand the operation status of the equipment, provide equipment maintenance suggestions and upgrade plans, and ensure long-term stable use of the equipment by customers.

Successful Cases

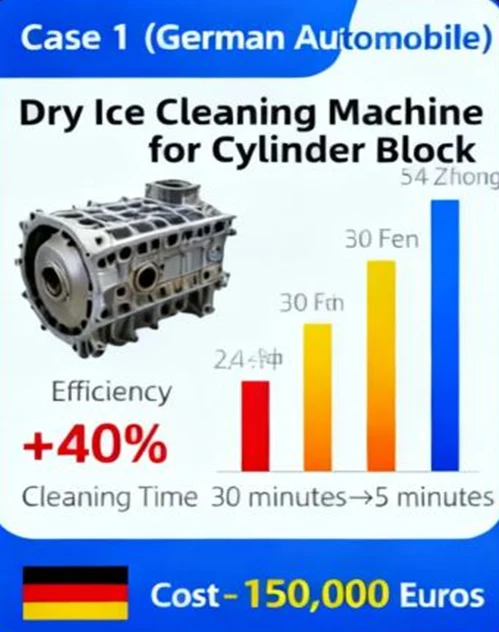

Case 1: A German Auto Parts Manufacturer

·Needs: Cleaning carbon deposits on engine cylinder blocks. Traditional chemical cleaning has low efficiency and leaves residues; there is an urgent need to improve cleaning efficiency and quality.

·Solution: Provide a fully automatic dry ice cleaning machine equipped with a customized cleaning tooling, enabling batch cleaning of cylinder blocks. The cleaning time per piece is reduced from 30 minutes to 5 minutes, with no residues after cleaning, and the cylinder block precision meets the standards.

·Results: The customer’s production line efficiency is increased by 40%, annual cleaning costs are saved by approximately 150,000 Euros, and the product qualification rate is increased from 98% to 99.8%.

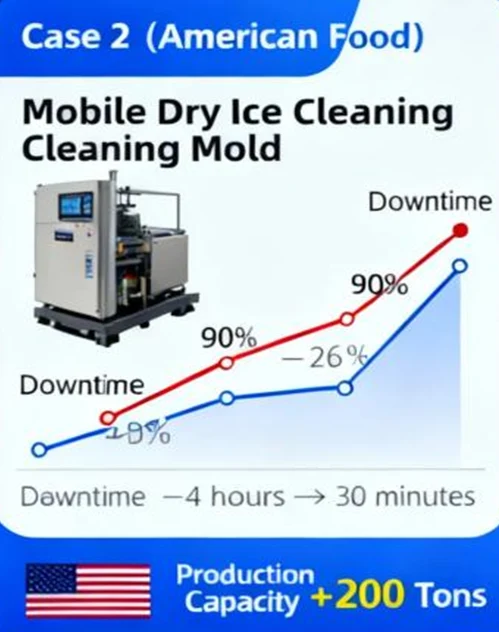

Case 2: A US Food Processing Plant

·Needs: Online cleaning of cookie baking molds. Traditional manual cleaning requires 4 hours of downtime per day, affecting production progress and easily causing cross-contamination.

·Solution: Configure a mobile dry ice cleaning machine for online cleaning of molds without disassembly. Each cleaning cycle is shortened to 30 minutes, and food-grade dry ice is used with no residues.

·Results: The customer’s downtime is reduced by 90%, annual production capacity is increased by approximately 200 tons, and the plant successfully passes the FDA hygiene inspection, enabling unobstructed export of products to the European market.

Case 3: A Chinese Electronic Equipment Manufacturer (Exporting to Southeast Asia)

·Needs: Dust collection in circuit board production workshops and air supply from air compressors, which must comply with the voltage (220V/50Hz) and environmental standards in Southeast Asia.

·Solution: Provide anti-static industrial dust collectors and oil-free air compressors adapted to 220V voltage. The dust collector has a filtration efficiency of 99.95%, and the oil content of the air compressor is less than 0.01mg/m³.

·Results: The dust concentration in the customer’s workshop is reduced to below 0.5mg/m³, complying with Southeast Asian environmental standards. The air compressor operates stably, and the failure rate of pneumatic equipment is reduced by 80%, ensuring the smooth entry of products into the Southeast Asian market.