This series of oil-free vortex air compressors focuses on medical grade clean compressed air as the core output. With oil-free vortex technology, high-efficiency design, and intelligent control, it demonstrates excellent performance in multiple fields such as medical, electronics, pharmaceuticals, food, and textiles. It produces clean and oil-free air, operates quietly and energy-saving, is reliable and durable, and has modular design and intelligent monitoring system. It can meet the high cleanliness needs of medical and other industries, and can adapt to various production scenarios through efficient energy efficiency and compact structure. It is the preferred compressed air solution that meets the needs of the times.

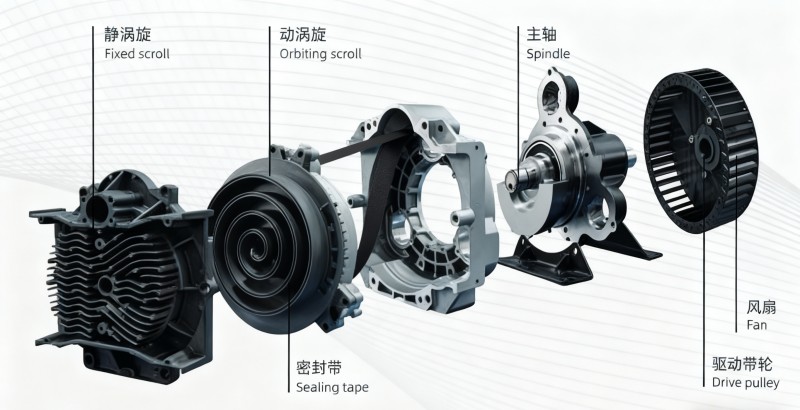

Providing medical grade clean compressed air, oil-free vortex technology ensures no metal to metal contact in the compression chamber, eliminating the need for oil lubrication and producing high-quality oil-free compressed air; At the same time, the energy utilization rate is high, and simple start stop/stop control is adopted to reduce unloading power loss. Variable flow control technology precisely matches the exhaust volume with air demand, resulting in significant energy-saving effects.

Featuring low noise and compact durability, the vortex component operates at low speeds to achieve ultra quiet operation and can be directly installed in the workplace; Compact design, small installation area, space saving; Less moving parts, able to operate for a long time, with fewer service times and strong reliability.

Featuring low noise and compact durability, the vortex component operates at low speeds to achieve ultra quiet operation and can be directly installed in the workplace; Compact design, small installation area, space saving; Less moving parts, able to operate for a long time, with fewer service times and strong reliability.

Providing clean and oil-free compressed air to ensure medical safety, such as dental equipment and oxygen therapy.

Provide clean compressed air for electronic component production in the assembly, cleaning, and gas supply processes to avoid pollution.

Used in the mixing process of the pharmaceutical industry to ensure a clean production environment and comply with strict standards in the pharmaceutical industry.

Applied in the brewing industry, such as mixing, to ensure the hygiene and safety of the food production process.

To provide power for jet looms and assist in the efficient operation of textile production.

We have had a stable cooperation with a leading automotive manufacturing company in Thailand for 5 years. In response to the high requirements for gas sources in the precision parts production line of the company’s Thai factory, we have customized and supplied compliant air compressors and provided local services, ultimately achieving 99.8% operational stability of the equipment, a 12% increase in production line yield, and an annual electricity savings of over 600000 Thai baht. We have also helped our customers pass environmental audits and become a benchmark for green factories.

We provide English user manuals, video training tutorials, and 24/7 online technical support.

built-in overvoltage protection valve, motor overload protection, and high temperature warning device; Clear safety operation signs are marked on the body, and automatic detection of pipeline pressure and circuit stability is carried out before startup to eliminate safety hazards.

| Filter Model | Flow Rate (m³/M) | Filter Cartridge Model | Number of Cartridges | Inlet/Outlet (Thread/Flange) | Cylinder Diameter |

|---|---|---|---|---|---|

| F-010 | 1–3 | 5-inch | 1 | 1-inch Internal Thread + Quick Open | 102 |

| F-050 | 4–6 | 10-inch | 1 | 1-inch Internal Thread + Quick Open | 102 |

| F-070 | 7–10 | 20-inch | 1 | 1.5-inch Internal Thread + Quick Open | 102 |

| F-100 | 10–20 | 20-inch | 2 | DN50 Flange | 180 |

| F-200 | 30–35 | 20-inch | 3 | DN65 Flange | 219 |

| F-300 | 40–55 | 20-inch | 5 | DN80 Flange | 255 |

| F-400 | 60–75 | 20-inch | 7 | DN80 Flange | 255 |

| F-500 | 80–100 | 20-inch | 9 | DN100 Flange | 325 |

| F-600 | 110–120 | 20-inch | 11 | DN125 Flange | 377 |

| F-700 | 130–140 | 20-inch | 13 | DN125 Flange | 377 |

| F-800 | 150–160 | 20-inch | 15 | DN150 Flange | 426 |

In stock, delivery within 3-7 workdays.

Accept OEM/ODM (e.g., customized dry ice feeding system, portable/industrial type), lead time 12-25 workdays.

Sample shipping methods: sea freight (FCL/LCL), air freight, express (DHL/FedEx/UPS/TNT).

Export-grade fumigation-free wooden crates, lined with shock-absorbing cotton; metal parts are treated for waterproofing and rust prevention.

Please provide the HS code, commercial invoice, packing list, certificate of origin, and customs clearance documents.

Payment methods: wire transfer (30% deposit in advance, 70% balance before shipment), letter of credit at sight, PayPal (sample orders ≤ USD 5,000).

18-month global warranty (core components: 24 months; consumable parts: 3 months).

We offer 24-hour online response via email/WhatsApp; overseas repair partners in the EU/US/Japan (on-site support within 3-5 business days); and free replacement of faulty parts during the warranty period.

Professional experience in the research and export of industrial cleaning equipment, with a professional foreign trade team (proficient in 6 languages) and over 30 R&D engineers.

Production capacity: 800 pieces/year, equipped with CNC machining centers, pressure testing instruments, and product performance testing laboratories.

Overseas layout: subsidiaries in Thailand, Germany (Munich), and the United States (Chicago); Singapore warehouse, can be quickly shipped to Southeast Asia (3-5 working days).

R&D capability: With over 15 global patents (such as energy-saving air distribution systems and adjustable dry ice feeding technology), it meets global environmental and safety standards.

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

A:Each product is different, please refer to the product introduction for details

Yes. We can, if you heed customized services, please contact us

A : FOB, CFR and CIF all acceptable.

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .