In industrial production, the dust generated by welding, cutting, polishing and other processes not only endangers the health of employees, but also affects product accuracy and production environment. EKM is deeply involved in the field of dust control and has launched six core dust collector products, covering all scenario needs such as universal, precision, and mobile. With a filtration accuracy of 99.9%+, flexible adaptability, and high cost-effectiveness, EKM provides customized solutions for small and medium-sized workshops to large manufacturing enterprises.

All products in the series use imported laminated filter media/polyester laminated filter media, with a filtration accuracy of up to 0.3 μ m, achieving a purification efficiency of over 99.9% for different pollutants such as metal particles, sawdust, and chemical dust; Some product innovations integrate wet dry dual effect filtration, which can cope with complex working conditions such as high temperature, oiliness, and viscosity, and prevent dust diffusion pollution.

From compact integrated (suitable for precision workshops with limited space) to mobile universal wheels (suitable for multi station mobile operations), from entry-level economy models (reducing investment for small and medium-sized enterprises) to high vacuum professional models (suitable for automated production lines), the six major products can be matched with welding, cutting, grinding, warehousing and other full scenarios, supporting mobile/fixed dual installation modes.

From compact integrated (suitable for precision workshops with limited space) to mobile universal wheels (suitable for multi station mobile operations), from entry-level economy models (reducing investment for small and medium-sized enterprises) to high vacuum professional models (suitable for automated production lines), the six major products can be matched with welding, cutting, grinding, warehousing and other full scenarios, supporting mobile/fixed dual installation modes.

Steel structure welding, plasma cutting, laser cutting, stainless steel polishing, aluminum alloy processing

Automotive parts, electronic components, medical devices, aerospace accessories, mold polishing

Automotive parts, electronic components, medical devices, aerospace accessories, mold polishing

Furniture processing, toy manufacturing, recycling of renewable resources, trial production of new materials, mixing of chemical raw materials

Temporary welding at construction sites, practical training in teaching laboratories, dust cleaning in warehouses, and processing of lithium battery materials

After cooperating with a large steel plant in Vietnam for 3 years, our dry wet integrated dust collector (EKM-11000DH) replaced the traditional bag filter, and improved the dust purification efficiency to 99.9% for high humidity and high air volume flue gas (processing 8000m ³/h per unit) in blast furnaces. The equipment maintenance frequency was reduced from twice a month to once a quarter, and the annual maintenance cost was reduced by 65000 euros. The zero dust emission function helps customers meet Vietnam’s “Industrial Waste Gas Emission Limits” and obtain local government green production certification.

Customize smoke and dust capture devices (such as suction arms, gas collection hoods) and pipeline systems, matching appropriate air volume models

We provide English user manuals, video training tutorials, and 24/7 online technical support.

A professional team visits to evaluate the working conditions and determine key parameters such as dust type, concentration, and operating area

| Product Name | model | Core parameters | Core Features | Adaptation scenario keywords |

| Smoke and dust purifier (universal basic model) | EKM-3000/EKM-6000 | Processing air volume of 3000-6000m ³/h, power of 4.0-7.5kW, 380V three-phase electricity | Sink flow design, oversized ash drawer, quick detachable filter cartridge, suitable for small and medium-sized fixed workstations | Steel structure welding, plasma cutting, furniture polishing, and dismantling of renewable resources |

| Integrated filter cartridge dust collector (precision compact version) | 3000/3000(EX)/3000TH(EX)/EKM-6000 | 处理风量 3000-6000m³/h,功率 3.0-7.Processing air volume 3000-6000m ³/h, power 3.0-7.5kW, noise ≤ 75dB | PLC intelligent control, built-in fan saves space, optional spark capture, 0.3 μ m high-precision filtration | Precision welding of automotive parts, electronic laser cutting, medical device processing, aerospace parts |

| Wet dry integrated dust collector (for complex working conditions) | EKM-3000DH/EKM-6000DH(EX)/EKM-7500DH/EKM-11000DH | Processing air volume 3600-11000m ³/h, power 3-11kW, suitable for high temperature/viscous dust | Wet dry dual effect filtration, corrosion-resistant body, integrated design with small footprint | Metal casting, casting and polishing, oil cutting, chemical raw material mixing, lithium battery material processing |

| Mobile welding smoke purifier (mobile operation model) | EKM-1000 | Processing air volume of 1200m ³/h, power of 0.75kW, 220V single-phase electricity, weight of 55kg | Metal casting, casting and polishing, oil cutting, chemical raw material mixing, lithium battery material processing | Mobile welding in hardware workshops, temporary work on construction sites, partial repair of ships, teaching and practical training |

| Simple high vacuum dust collector (entry-level economy model) | EKM-S-11 | Processing air volume of 110m ³/h, power of 0.55kW, 220V single-phase electricity, weight of 35kg | Simplify design to reduce costs, capture high vacuum sources, and eliminate the need for direct piping | Start up enterprise single station welding, small robot assisted purification, furniture repair, electronic repair |

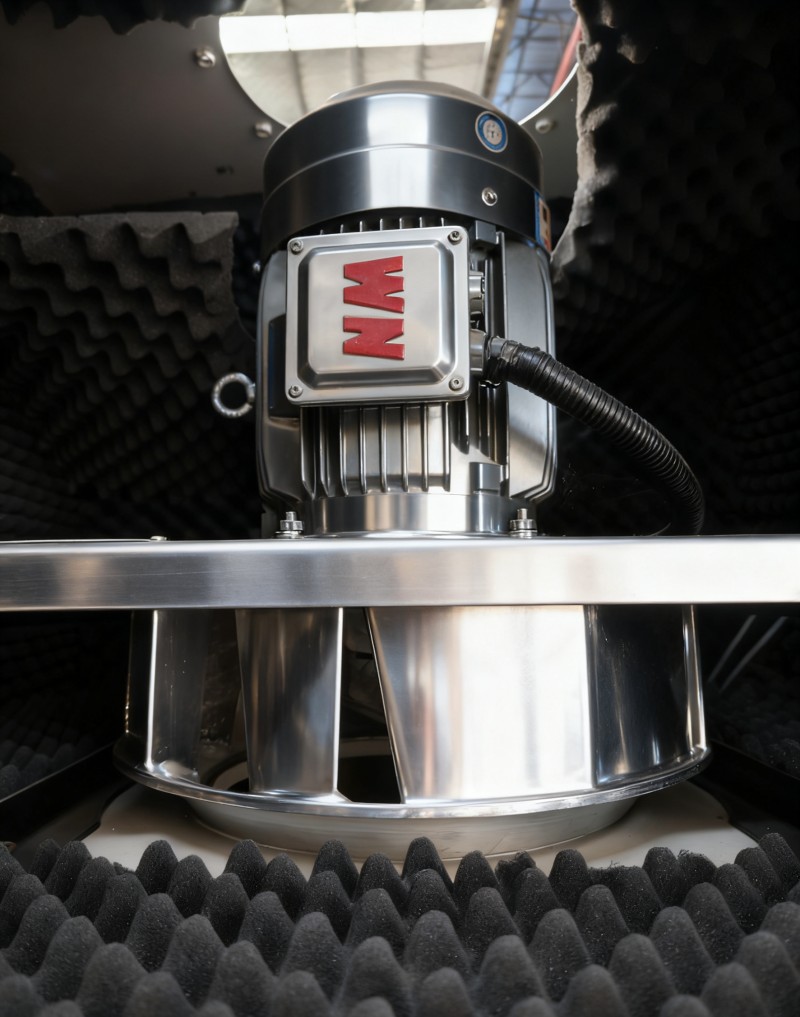

| Integrated high vacuum dust collector (professional advanced version) | HF-150 | Processing air volume of 150m ³/h, power of 3.0kW, 380V three-phase electricity, weight of 110kg | Strong suction continuous operation, wear-resistant hose, suitable for automated production lines | Automated robot welding, precision hardware polishing, aluminum alloy processing for doors and windows, and warehouse dust cleaning |

In stock, delivery within 3-7 workdays.

Accept OEM/ODM (e.g., customized dry ice feeding system, portable/industrial type), lead time 12-25 workdays.

Sample shipping methods: sea freight (FCL/LCL), air freight, express (DHL/FedEx/UPS/TNT).

Export-grade fumigation-free wooden crates, lined with shock-absorbing cotton; metal parts are treated for waterproofing and rust prevention.

Please provide the HS code, commercial invoice, packing list, certificate of origin, and customs clearance documents.

Payment methods: wire transfer (30% deposit in advance, 70% balance before shipment), letter of credit at sight, PayPal (sample orders ≤ USD 5,000).

18-month global warranty (core components: 24 months; consumable parts: 3 months).

We offer 24-hour online response via email/WhatsApp; overseas repair partners in the EU/US/Japan (on-site support within 3-5 business days); and free replacement of faulty parts during the warranty period.

Professional experience in the research and export of industrial cleaning equipment, with a professional foreign trade team (proficient in 6 languages) and over 30 R&D engineers.

Production capacity: 800 pieces/year, equipped with CNC machining centers, pressure testing instruments, and product performance testing laboratories.

Overseas layout: subsidiaries in Thailand, Germany (Munich), and the United States (Chicago); Singapore warehouse, can be quickly shipped to Southeast Asia (3-5 working days).

R&D capability: With over 15 global patents (such as energy-saving air distribution systems and adjustable dry ice feeding technology), it meets global environmental and safety standards.

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

A:Each product is different, please refer to the product introduction for details

Yes. We can, if you heed customized services, please contact us

A : FOB, CFR and CIF all acceptable.

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .