Dry ice cleaning machines are a high-performance industrial solution designed for industries such as automotive manufacturing, electronic component processing, and mechanical engineering. Compared to traditional models, they are 35% more energy-efficient and use 3mm granular dry ice (low ice consumption), effectively solving the problems of high operating costs and inconsistent processing accuracy in global production lines.

This product complies with key certifications such as EU CE, US UL, and ISO 9001, and has been exported to more than 50 countries, including Germany, the United States, Japan, and Southeast Asia, serving more than 2,000 international customers.

Equipped with a low-temperature motor to ensure stable power output under low-temperature conditions; equipped with a Huichuan or equivalent frequency converter to achieve precise speed and power control, ensuring high efficiency and energy saving in cleaning operations.

In terms of control components, SMC or Yadac solenoid valves are used, which have sensitive action and strong sealing performance, which helps to accurately switch the pneumatic system; at the same time, Schneider Electric components are integrated, with the quality assurance of an internationally renowned brand, to ensure the stability and safety of the equipment’s electrical system.

In terms of transportation and weather resistance, it is equipped with thickened low-temperature dry ice tubes, which can withstand the extremely low temperatures during dry ice transportation and ensure the stable transmission of dry ice medium; a new oil removal protector has been added, which can effectively purify the gas source and avoid oil contamination from adversely affecting the equipment and cleaning effect.

With the help of an automatic drain valve and a pressure regulating valve, intelligent drainage and precise pressure regulation of the gas source can be achieved, further optimizing the performance of the gas system.

The core turntable adopts an aluminum alloy hard anodizing process (an industry-leading technology), which combines high strength, high wear resistance and excellent corrosion resistance to ensure long-term stable operation of the equipment. In addition, it is equipped with a complete set of protective equipment to ensure the safe operation of operators.

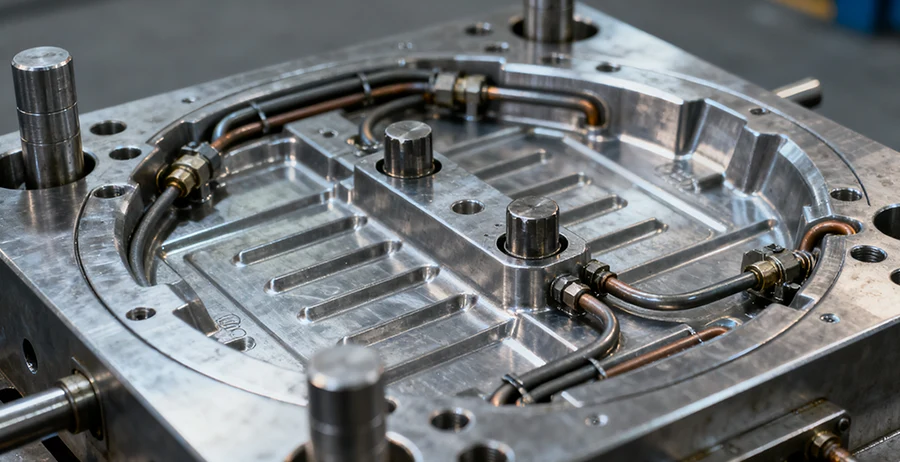

Automotive industry: Mold cleaning (injection molds, die-casting molds), engine/transmission maintenance, production line equipment cleaning.

Conveyor belts, mixing equipment, and packaging machines (no chemical residues, meeting food safety standards).

Cleaning of aircraft engine components and fuselage surfaces (using non-abrasive cleaners for sensitive components).

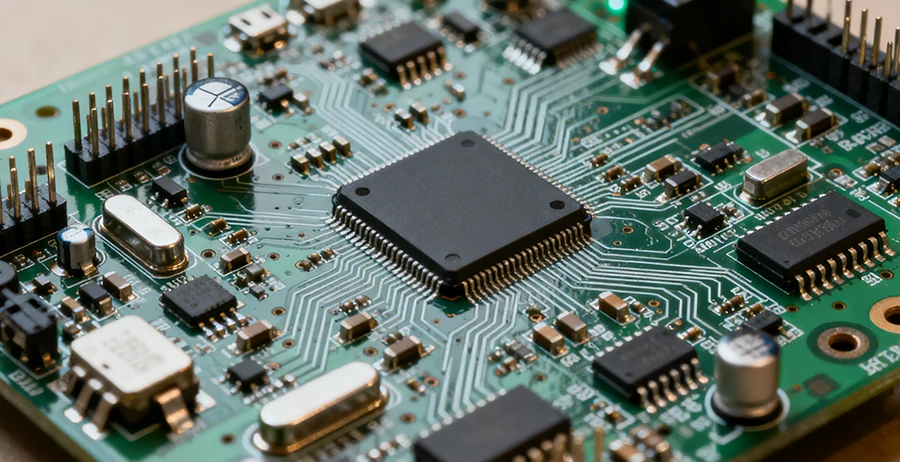

Circuit boards and production equipment (to prevent damage from moisture and ensure the safety of precision electronic products).

Rubber, plastic, and die-casting molds (can be quickly cleaned without disassembly).

We have been working with a leading Spanish automotive parts manufacturer for four years. Our dry ice blasting equipment replaces traditional sandblasting and chemical cleaning processes, reducing mold cleaning time by 65% and saving €80,000 in maintenance costs annually. The zero-waste nature helps our client meet EU environmental regulations and obtain green production certification.

No complicated installation required; simply connect to a compressed air source and dry ice supply to start.

The lightweight cleaning gun features adjustable pressure, reducing operator fatigue.

We provide English user manuals, video training tutorials, and 24/7 online technical support.

It is equipped with a pressure relief valve, overheat protection, and safety operation instructions.

| Model | GT-20 | GT40 |

| Compressed air flow | > 2.5 cubic meters/minute | > 3.5 cubic meters/minute |

| Gas supply pressure | 0.4-1.6MPa | 0.4-1.6MPa |

| Dry ice ejection rate | 0-2.0 kg/min | 0-3.0 kg/min |

| dry ice capacity | 12-15 kg | 20 kg |

| Dry ice state | 3 mm particles | 3 mm particles |

| Motor power | 0.8kilowatts | 0.8kilowatts |

| Dimensions (Length x Width x Height) | 509* 757 * 1085 (mm) | 509* 957 * 1100 (mm) |

| Equipment weight | 85 kg | 100 kg |

| Equipped with power supply | 220 volts/50 Hz | 220 volts/50 Hz |

| Standard Annex 1 (Air Connection Pipe) | 8m Φ 12mm compression | 8m Φ 12mm compression |

| Standard accessories 2 | gunstock | gunstock |

| Standard accessories 3 | straight nozzle | straight nozzle |

In stock, delivery within 3-7 workdays.

Accept OEM/ODM (e.g., customized dry ice feeding system, portable/industrial type), lead time 12-25 workdays.

Sample shipping methods: sea freight (FCL/LCL), air freight, express (DHL/FedEx/UPS/TNT).

Export-grade fumigation-free wooden crates, lined with shock-absorbing cotton; metal parts are treated for waterproofing and rust prevention.

Please provide the HS code, commercial invoice, packing list, certificate of origin, and customs clearance documents.

Payment methods: wire transfer (30% deposit in advance, 70% balance before shipment), letter of credit at sight, PayPal (sample orders ≤ USD 5,000).

18-month global warranty (core components: 24 months; consumable parts: 3 months).

We offer 24-hour online response via email/WhatsApp; overseas repair partners in the EU/US/Japan (on-site support within 3-5 business days); and free replacement of faulty parts during the warranty period.

Professional experience in the research and export of industrial cleaning equipment, with a professional foreign trade team (proficient in 6 languages) and over 30 R&D engineers.

Production capacity: 800 pieces/year, equipped with CNC machining centers, pressure testing instruments, and product performance testing laboratories.

Overseas layout: subsidiaries in Thailand, Germany (Munich), and the United States (Chicago); Singapore warehouse, can be quickly shipped to Southeast Asia (3-5 working days).

R&D capability: With over 15 global patents (such as energy-saving air distribution systems and adjustable dry ice feeding technology), it meets global environmental and safety standards.

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

A:Each product is different, please refer to the product introduction for details

Yes. We can, if you heed customized services, please contact us

A : FOB, CFR and CIF all acceptable.

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .